I got two sets of machinists squares.

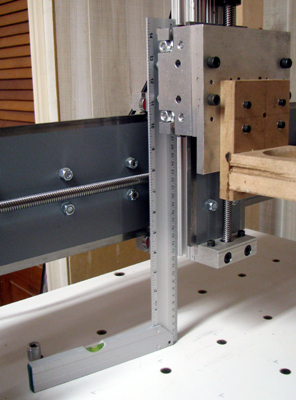

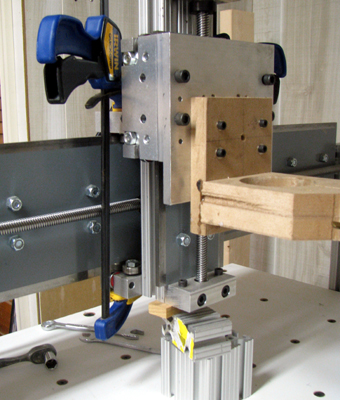

Check the height of the gantry CRS plate. Make sure it's the same on both ends.

Check the Z rails for tilt.

If you have to adjust, remember to block up the Z-axis when you loosen

the screws holding on the linear slides.

Also check the Z axis mounting plate for tilt.

Adjust the gantry rail if necessary.

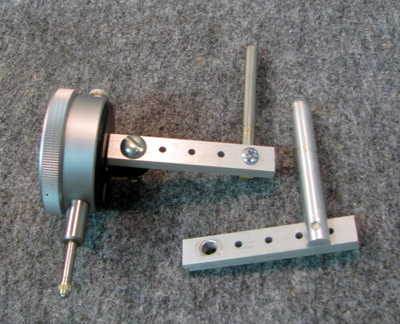

I made a mount for my dial indicator to fit into my mill spindle.

Then I made one for my trim router (the thinner one).

It's based on a Spindle Head Tram Gage sold by Validus Group.

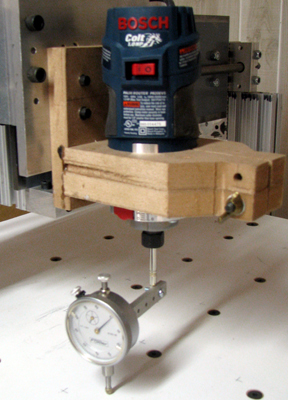

Dial indicator mounted in the spindle.

You can tell quickly if the spindle is not vertical.

I also mounted my dial indicator directly on the z-plate to measure

the flatness of the work surface.

If you do this, don't raise the z-plate too much!