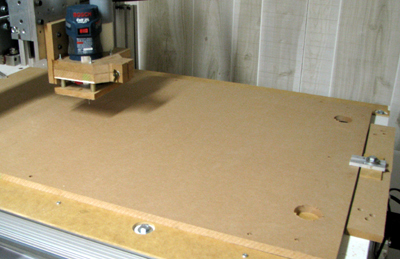

Clamp the MDF to the CNC table while you cut the

mounting holes and the vacuum inlet ports.

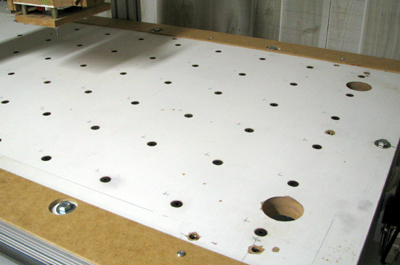

Cut the mounting holes and vacuum ports into the CNC

table. (ouch!)

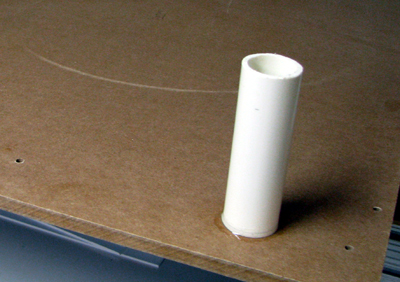

Here's what the vacuum plumbing looks like. This goes

under the table so don't glue the pipes together!

Just glue the short risers into the MDF. Make the holes

in the CNC table oversize to clear the glue bead.

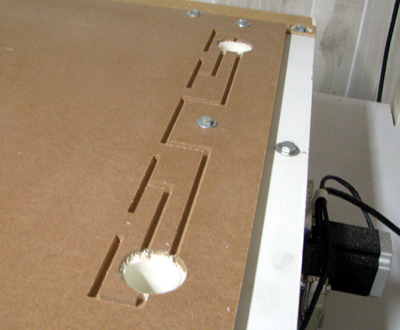

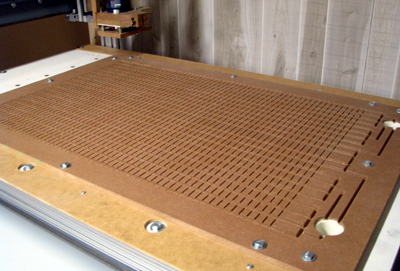

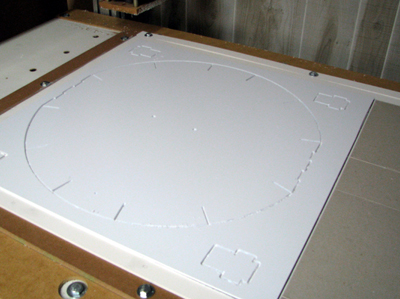

MDF now bolted onto CNC table and vacuum ports cut.

See my notes below on do-overs. Those slots are too small.

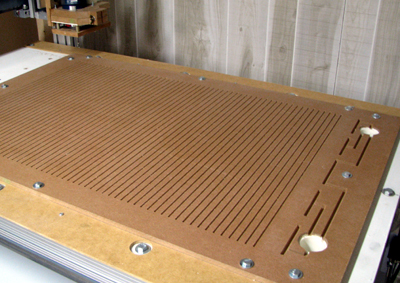

vertical slots cut into the MDF

And now the horizontal slots cut as well.

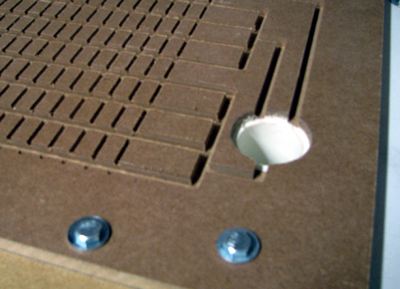

closeup of feed slots and H&V grid slots.

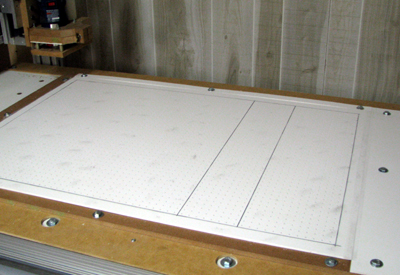

shown here the working surface is a piece of expanded PVC

sheeting. My next set of working surfaces will be tempered

hardboard. (It's cheaper!) - the holes are .1 dia on .5 centers

Typical cut of a 20x20 piece of styrene.