First Cut

How

do you really know your cuts are coming out in the right place?

I asked that question in the previous section. This time I'm actually making cuts with the router!

I'm

still using circles and squares. This time I'm cutting 4 six inch

circles inside 4 seven inch squares. The dimensions were chosen to

accommodate the material I had on-hand (pieces of paneling left over

from finishing the basement). I modified the diagnostic software to

deal with cutting real material instead of drawing lines. Instead

of creating one g-code file the program writes three files. You can download the python code and the test files

if you like. Run all three without turning off the stepper drive so

that you don't loose the origin location. Mark the panel so that you

know the orientation of the circles and squares after they are removed

from the router.

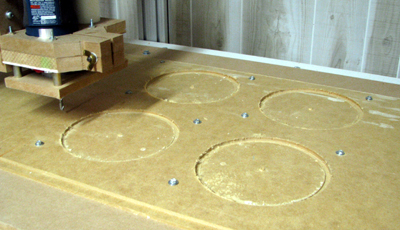

For my first set of cuts I used a 1/4 inch router, feed rate of 30 ips, making one .175 cut in MDF paneling.

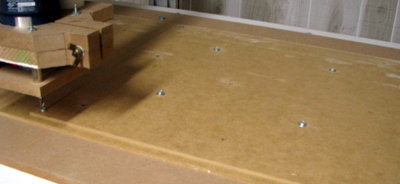

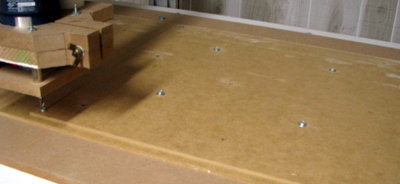

test_cut1 'drills' the center holes in the circles and two corner holes in each square.

After cutting the holes I put hold down screws in the circle center holes.

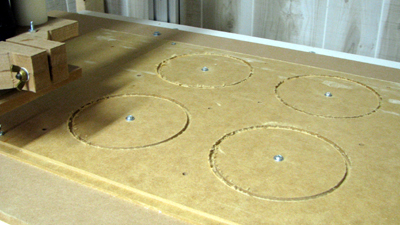

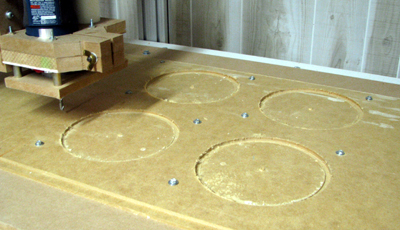

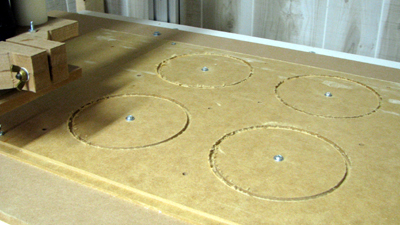

test_cut2 cuts out the circles.

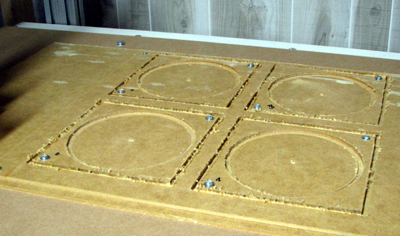

After cutting the circles, remove the center hole screws and the circle pieces. Then put hold down screws in the squares.

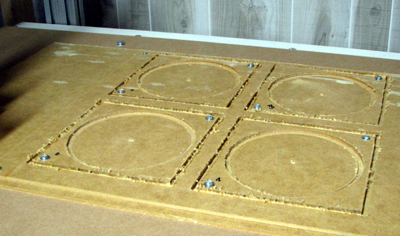

test_cut3 cuts out the squares.

Using the router to 'drill' the hold down bolt locations. |

Circle hold down bolts in place. |

|

All the circles have been cut and the dust has been cleaned up. |

square hold down bolts in place. |

|

All the squares cut and dust cleaned up. | (not shown) - lightly sand the edges to remove the MDF and paneling 'fuzz'.

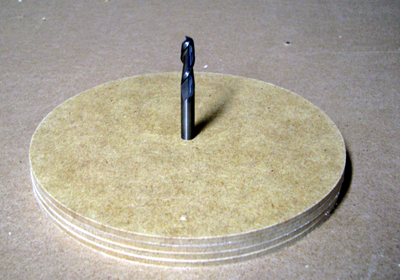

Now for the real testing. The reason for cutting 4 circles and squares.

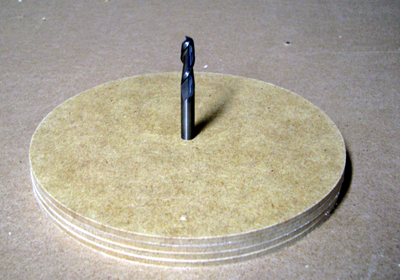

Stack

all 4 circles using a router bit as a shaft. You did remember to put an

orientation mark n the circles? [I didn't! - damm...] Rotating the

circles relative to one another will quickly tell you if they are round

or not.

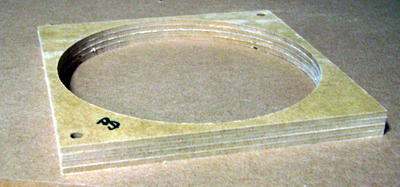

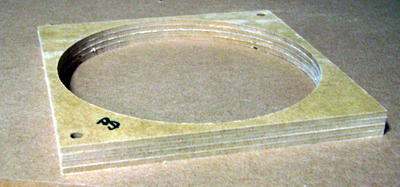

Stack all 4 squares. Check for alignment. Then rotate the

2nd square 90 degrees, the 3rd 180 degrees and the 4th 270 degrees. [An

additional quarter turn on each level of the stack]. Again, you should

be able to tell if you've got squares. The edges should line up

perfectly.

If the edges don't line up go back to the alignment section and check everything again. |

|  |

Gotchas: I'm

slightly off. You can just barely see it in the pictures above. I think

my gantry is twisted relative to base frame. I've got to go back and

adjust it. Then I'll try again.